By Achim Heringderivative work: Mircalla22 (talk) - 07840drw1.jpg, CC BY 3.0, https://commons.wikimedia.org/w/index.php?curid=7647697

In 1996, an electrical fire occurred at 30 Rockefeller Plaza in New York City, for up to 40 years previous to this, the fire-protection community had been very concerned regarding the quality of protection around penetrations. When firefighters arrived at the scene in Rockefeller Plaza, they found that multiple fires had broken out in five different locations, therefore filling much of the building with smoke.

According to the report on the fire from the National Fire Protection Association, it was the unprotected horizontal and vertical penetrations that had allowed the rapid spread of the fire and smoke. These openings also allowed the smoke from the fires to spread outside of the electrical rooms and into floors with occupants.

This incident was not a once off, as there have been many similar fires to this that have really emphasized the need for fire-stopping around penetrations, especially by electrical installations. The building and electrical codes were both updated to reflect this updated need for quality fireproofing.

Firestopping: The Basics

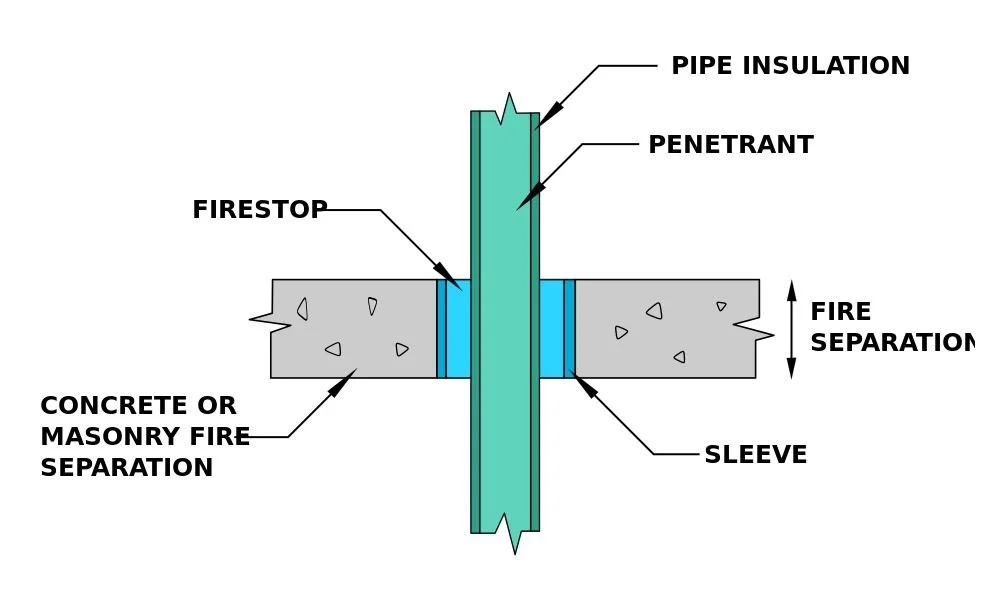

To ensure that fireproofing is done properly, you have to understand the basics of it. There are three elements to fire stopping: the fire-rated partitions, walls, floors, and ceilings being penetrated, the methods and materials used to seal the penetrations, and the object that is creating the penetration. In addition to these, the architect or interior designer must consider whether the penetrations will be permanent or not, as they might change due to a new tenants’ renovations which might require new systems. Permanent penetrations will typically be those used for the main building power, heat, or cooling.

The Language of Fire Stopping

Fire stopping materials are made by a number of manufacturers. A lot of them put together their own Underwriters Laboratories (UL) documentation regarding to their product and how to install it. UL will test these products and will then publish a listing based on the application of the product. This number format groups these products together using a two-letter format in their directory.

Their format is as follows:

The first letter of the format determines the type of penetration through a fire-rated structure:

C for penetrations through the wall and floor

F for penetrations through the floor

W for penetrations through the wall

The second letter of the format determines the type of construction:

A for concrete floors smaller than or equal to five inches thick

B for concrete floors more than five inches thick

C for floors that are framed

D for deck construction

J for masonry or concrete wall smaller than or equal to eight inches thick

K for masonry or concrete wall more than eight inches thick

L for walls that are framed

M for bulkheads

There is then a number grouping that follows the two letters to identify the items that are penetrating. For instance, these numbers might display 1000 to 1999 for different types of metal conduit, tubing, or pipe, or 3000 to 3999 for different types of cables.

Fire Stopping Installation Methods

When an object passes through a wall for instance, a contractor can fill the opening with fire stopping material. A lot of fire stopping products take advantage of intumescent materials, these are materials that expand when they are exposed to heat, so that they can fill any potential voids in the penetration. Generally these products are fire-stop caulk, mortar, blocks, putty sticks, and pillows.

Fire-stop caulk and mortar are semi-permanent products. The mortar is typically applied by the contractors with a trowel, and the caulk with a caulk gun. Putty sticks can be molded around the object that is causing the penetration, and contractors can install fire pillows or blocks when stacking materials and forming them to block up large penetrations.

By Achim Hering - Own work, Public Domain, https://commons.wikimedia.org/w/index.php?curid=2258260

The above materials and application methods should be sufficient to properly fire-stop penetrations, however their effectiveness could be compromised if there are any changes made to the penetration, when the provided fire stopping details are not followed properly and the penetration is difficult to inspect. Some of these materials, especially the putty and caulk, are quite difficult to inspect once installed. Also as mentioned previously, some penetrations are not permanent, so once any changes are made to the systems and penetrations, the fire stopping will need to be re-done and re-inspected.

Materials like caulk and mortar will have to be taken out entirely and installed again. Putty does not harden and crack, but the contractor must ensure that the changes do not lessen the effectiveness of the putty.

Pillows and blocks are specifically designed to be able to be taken out and re-installed, so there should be no problems with them.

It is critical to understand that the contractor (not the engineer!) is responsible for the fire-stopping installation. They should know the hourly rating of the fire-stopping, the products used, and the hourly rating of the fire barrier that they are matching.

So, what do you think of these methods of installing fire-stopping? Do you have anything to add to this article, if so please let us know in the comment below. If you are looking for special inspectors for your next project don’t hesitate to contact Engineering Solutions!